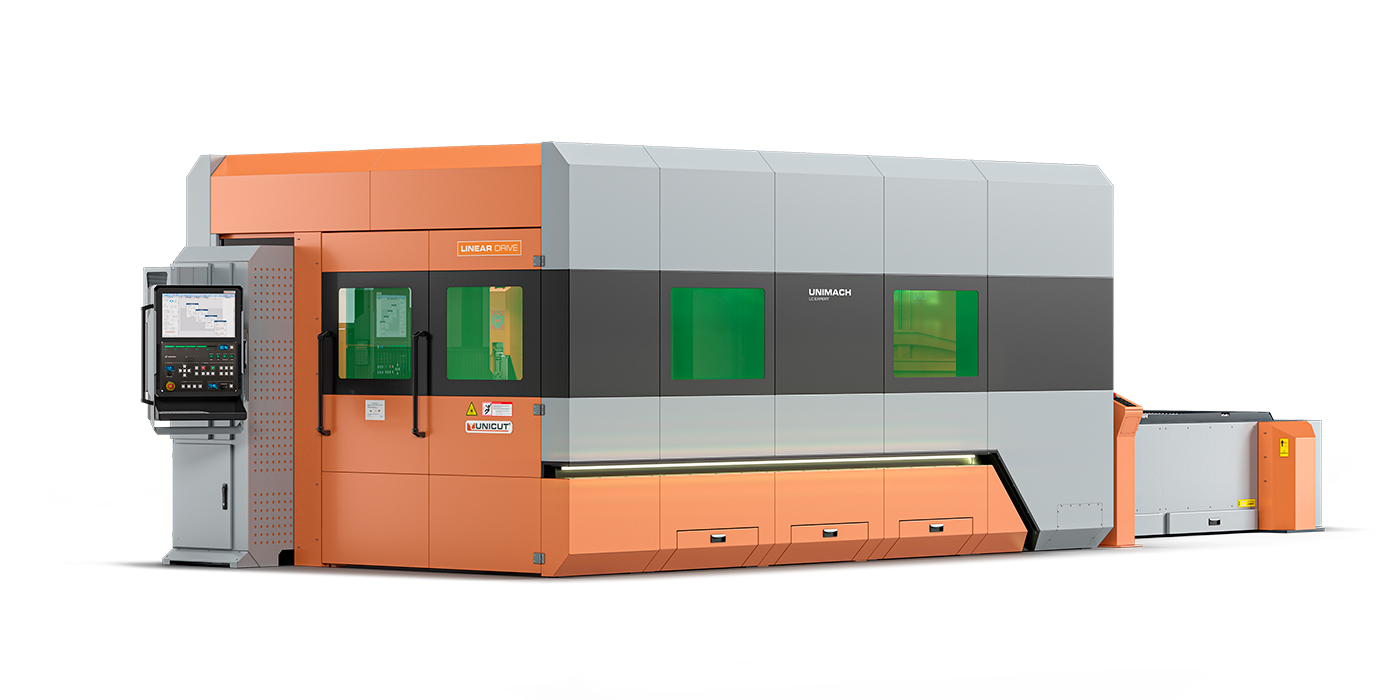

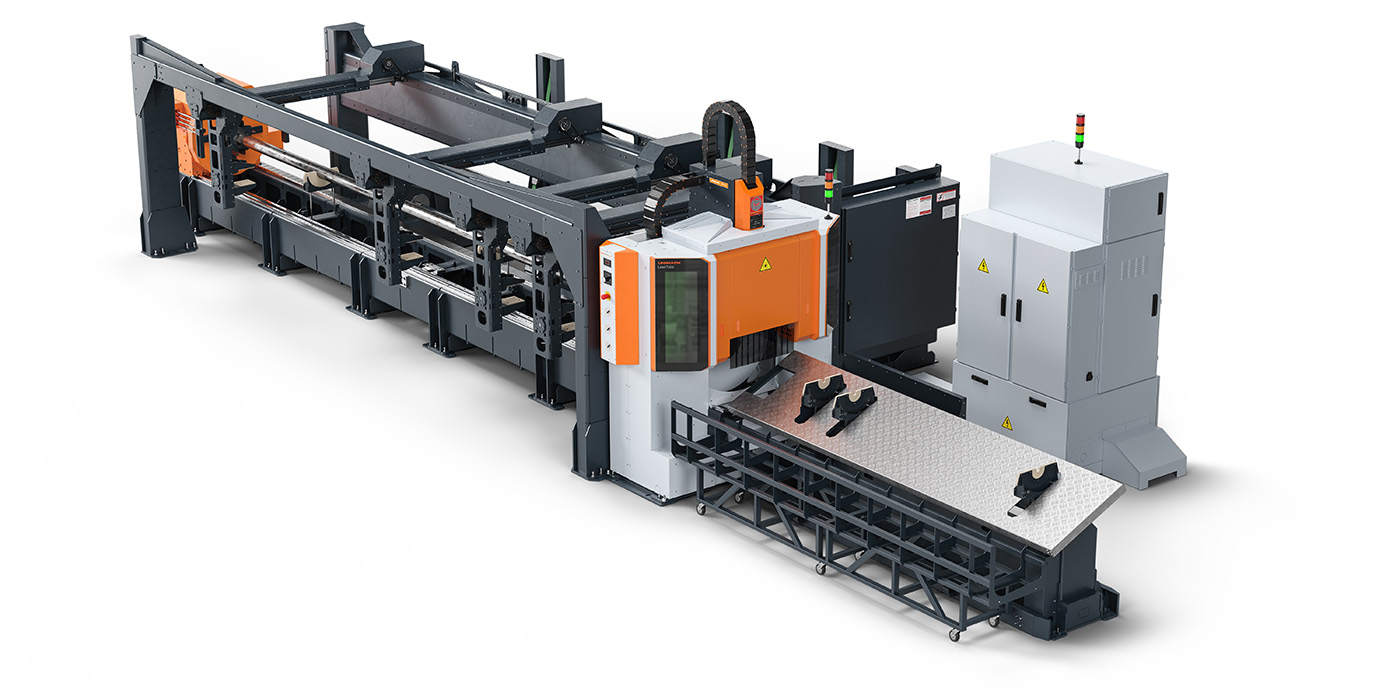

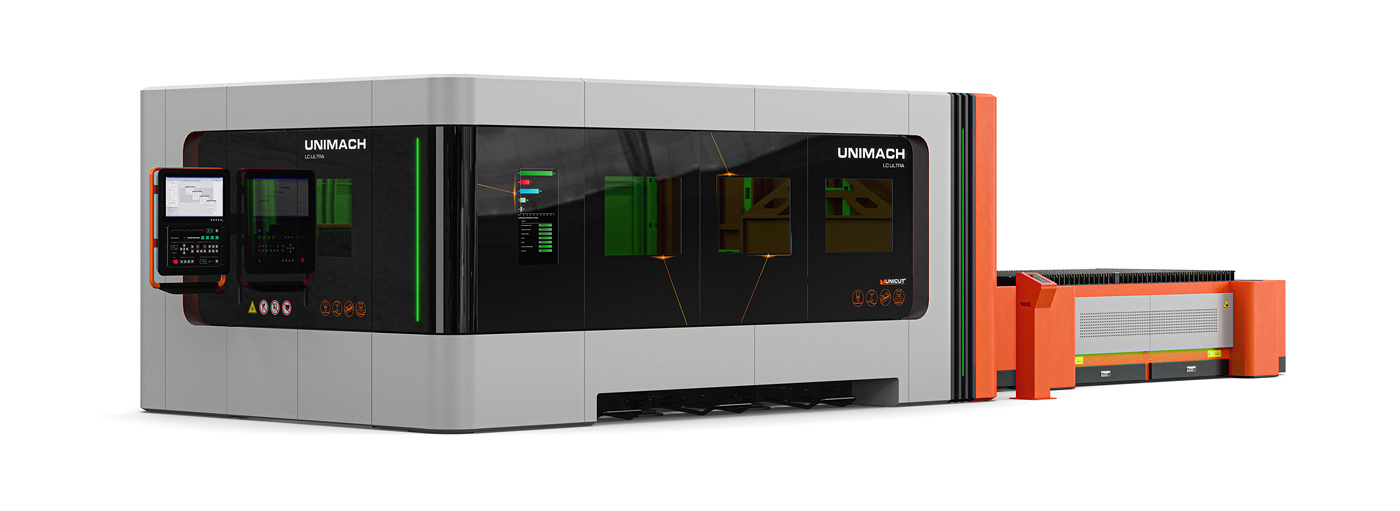

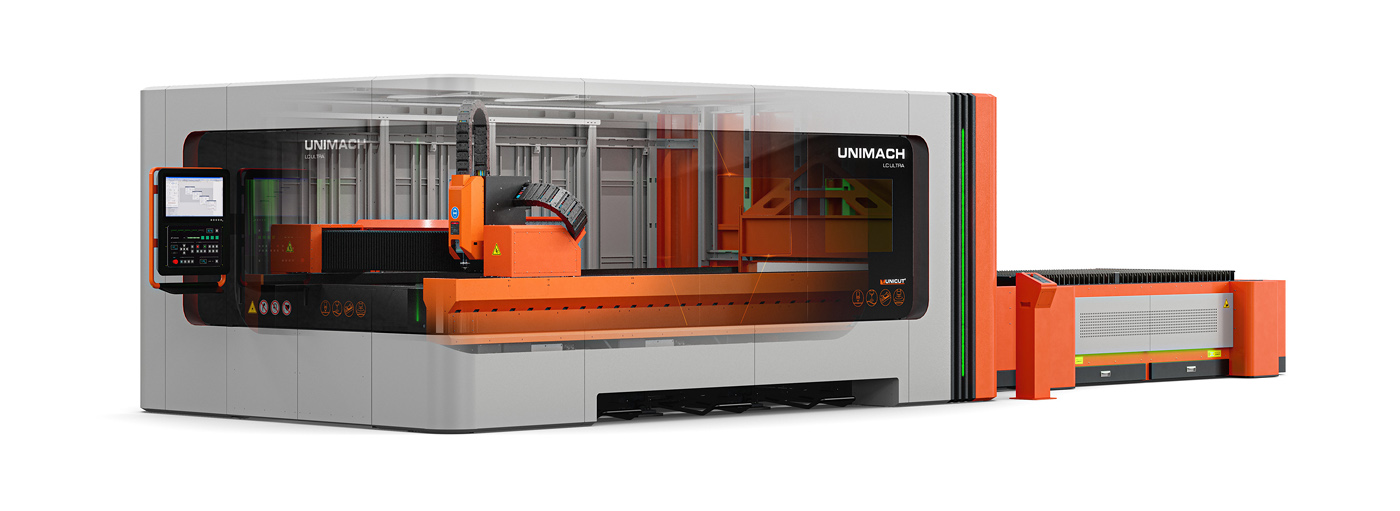

Laser cutting machine LC 3015 Ultra shows the highest productivity, maximum efficiency and perfect cutting quality. Unparalleled power of the linear drive paired with state-of-the-art electronics and digital data bus enable to reach unprecedented acceleration and speed of free travel, as well as high-precision cutting of all contours – from simple to complicated filigree ones.

The machine LC Ultra is a perfect solution for Medium & Large Enterprise ensuring strict tolerance control and minimization of defects.

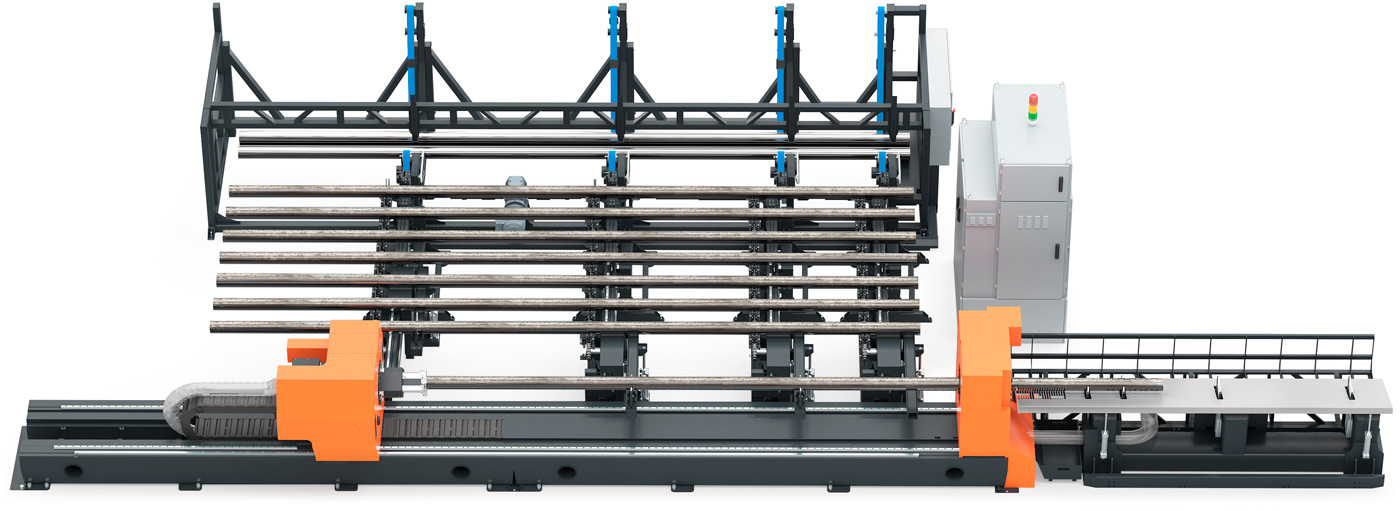

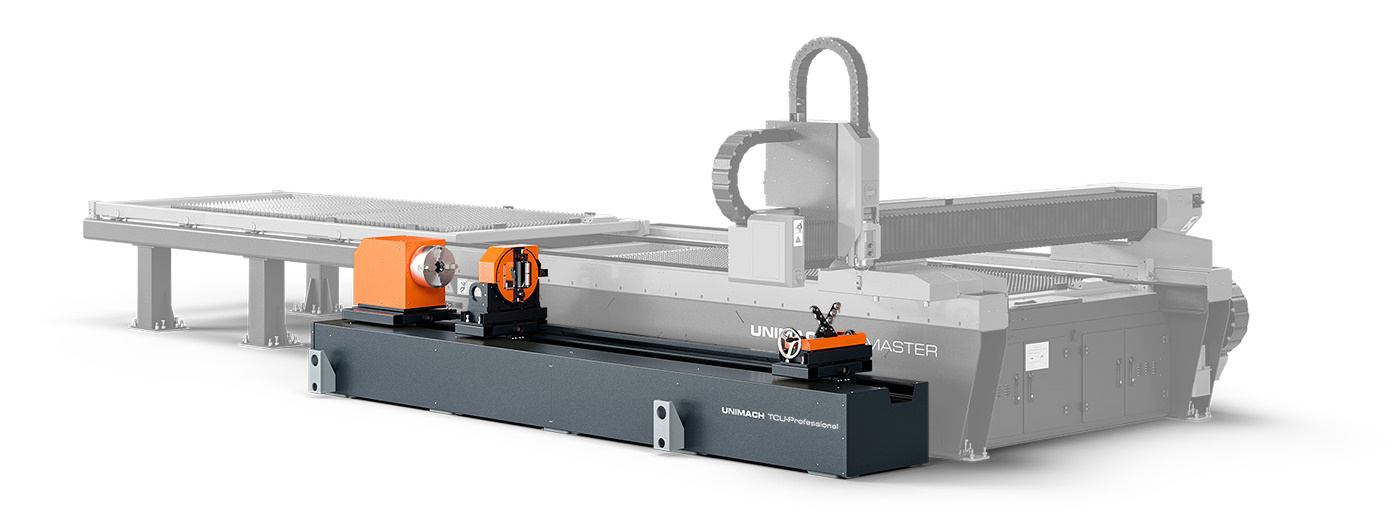

The conceptual difference of the model lies in the highest level of automation at all operation steps – from the servicing and retooling to loading of workpieces into the cutting zone. This enables to simplify an operator’s work and minimize an impact of human factor on the end product.

Unimach machinery is manufactured in St Petersburg using our own components.

Standard equipment

Rigid all-welded heat-treated machine bed with subsequent machining;

Gantry coordinate system;

Lightweight composite material;

High precision guide, integrated feedback;

Linear drive, axes X, Y, servo drive with feedback sensors of axis Z;

Zoned smoke exhaust system with automatic zone switching;

Ytterbium fiber laser IPG Photonics;

Cooling system water / air (chiller);

Focus length control system FoCut;

Laser optical head LH-110 with automatic drive of focus lens;

Control console UM-103 (IP65, industrial LCD 21", stationary control panel, pull-out keyboard);

Software UniCut;

Automatic 4-gas console (2 gases up to 10 atm, 2 gases up to 20 atm);

Protective enclosure of the cutting area with an access to the working table;

Automatic shuttle table;

Remote control panel;

Centralized lubrication system;

Exhaust fan;

SPTA kit;

Commissioning works and personnel training.

Main features

IPG laser

Kilowatt-class fiber lasers applied in LC 3015 Ultra represent some undeniable advantages compared to other types of lasers. They do not require any complicated maintenance: supervision of skilled personnel or consumables are no longer needed. The fiber laser is the most reliable among the existing ones. The operating lifetime exceeds a decade due to the entirely sealed body that contains the dryer and enables operation in the harsh industrial environment.

Beam delivery

A beam is delivered by a fiber-optic path without mirrors. The fiber system is absolutely dependable; its lifetime can be compared to the laser itself.

Optical laser cutter LH-110

LH-110 takes the automation processes to the next level. The built-in lens drive enables to adjust the focus length automatically making settings of the cuttings modes a lot easier. The adjustment occurs automatically when an operator selects a material from the UniCut library.

The cutter is equipped with the cartridge system of lens and protective glass replacement enabling to reduce the service time and protect against dust penetration to the laser body.

Gear and drive

LC 3015 Ultra is equipped with the high power linear drive and state-of-the-art digital data bus. These solutions enable to reach unparalleled free movement speed and acceleration leading to high efficiency cutting even of the most complicated contours.

Lubrication system

The machine is equipped with the automatic lubrication system: it lubricates all main parts as soon as the maintenance time comes. The machine is being lubricated in operation/running and do not require operator’s supervision or actions.

Zoned smoke exhaust system

Our machine is equipped with the zoned smoke exhaust system. Only the area where the cutter is currently working is connected to the ventilation system. This solution makes it possible to exhaust smoke with extreme efficiency and, at the same time, to use less powerful ventilation system.

Cooling system

The machine is equipped with water / air cooling system providing efficient cooling and water cost reduction.

Gas console

Blowing of the working area with an assist gas is crucial during metal cutting. LC 3015 Ultra is equipped with 4-gas console with a CNC integrated interface. The console automatically switches the cutting gas and sets its pressure from the UniCut Library.

Nozzle cleaning and calibration system

Checking the condition of the laser head nozzle is highly important to maintain high quality cut. Cutting waste may adhere to the nozzle surface, disrupt the operation of the capacity sensor, and lead to a collision with the metal surface. Laser cutting machine LC Ultra features a special function – automatic nozzle cleaning. The cleaning initiates after a certain number of piercings. The optical head moves towards the cleaning area, the brush cleans the nozzle, and then it returns to the initial position.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Laser Cutting Machine

Laser Cutting Machine

.png)

.png)