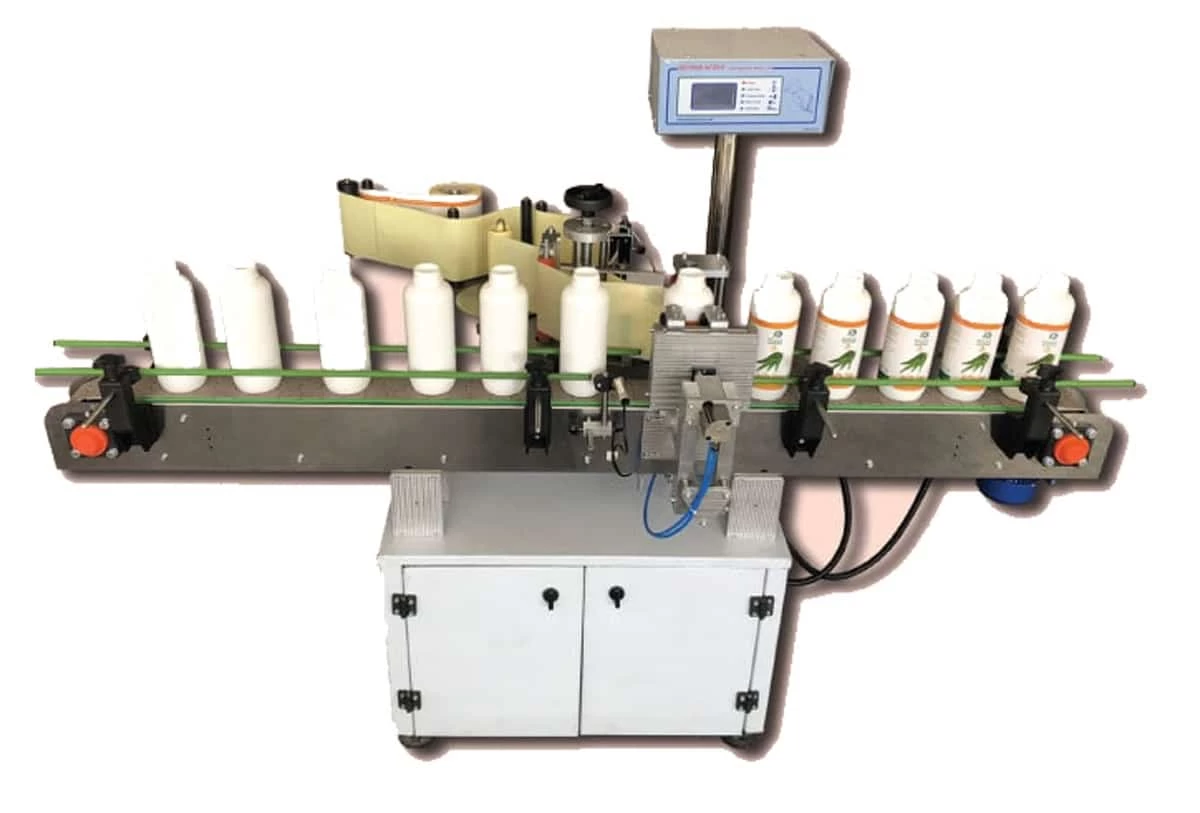

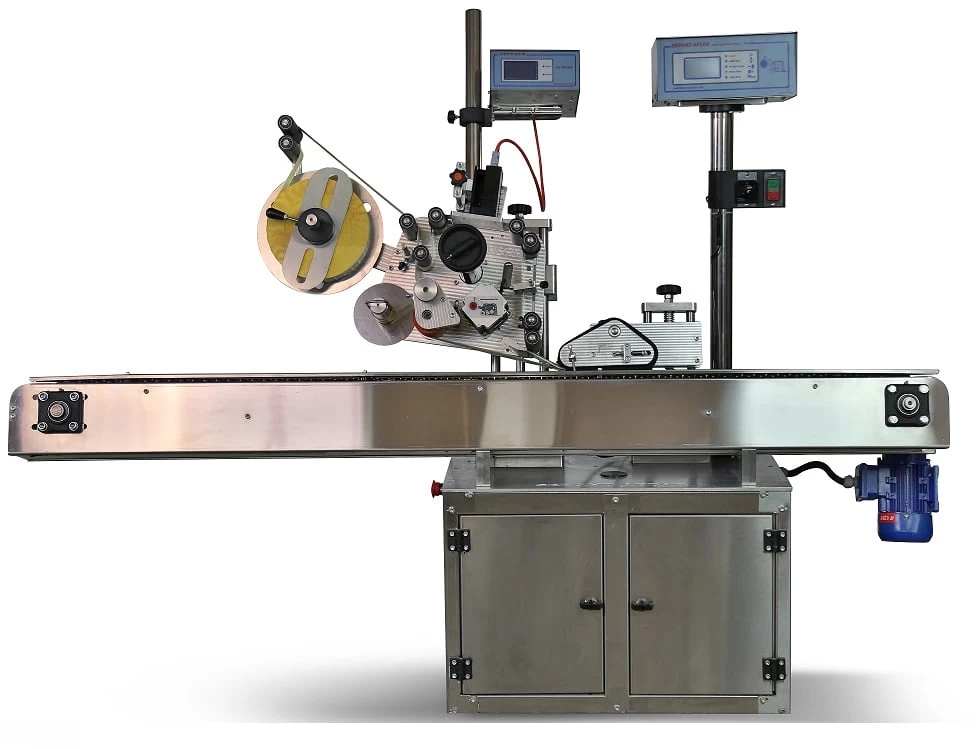

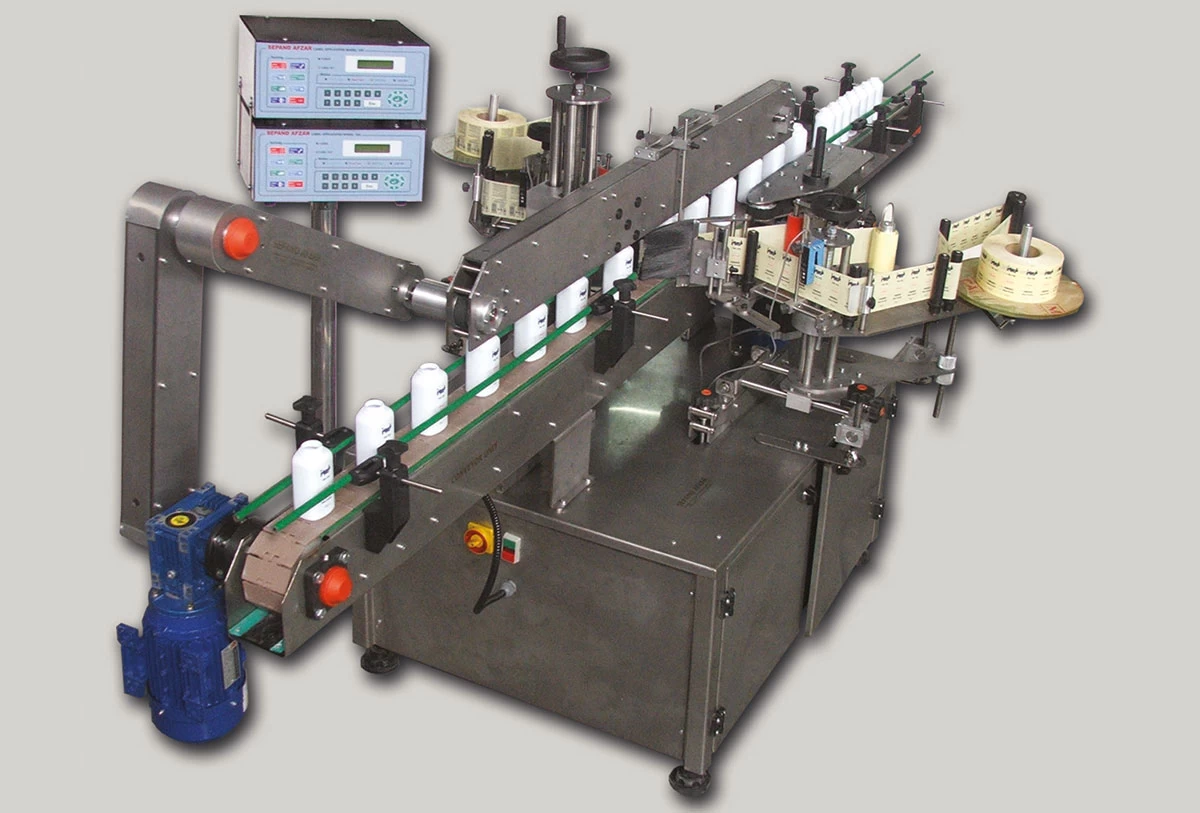

It has an aluminum mechanical plate, mechanical settings and the angle of the respective feeders and a cross elevator to adjust the position of the label (an elevator with easy and very precise adjustment).

The ability to connect to all kinds of automatic filling and capping lines

It has engineering settings (Setup Eng) including: motor direction, maximum line speed, Auto power off and Label out duration.

It has a label error reporter in Farsi language and how to fix the corresponding error

It has a special spacer system (depending on the type of container and customer order)

Equipped with an advanced and portable microcontroller with a touch LCD screen and ten label memories (with Farsi menus)

It has a stepper motor with an accuracy of 0.72 degrees (±1 mm) and a servo motor if needed

It has operator settings including: delay in labeling, stop label, sensitivity of the label skin, motor speed, label memory, etc., can be ordered at high speeds and using servo motor.

With automatic calibration of labels and skins in Farsi language

Made according to materials and facilities approved by pharmaceutical companies

Send message to author

Pharmaceutical adhesive label

2023-09-10 06:23:41

Comments

Related posters

© 2024 Copyright: mallmir.com

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Printing Machine

Printing Machine