The ability to fill all kinds of dairy products such as school milk, cocoa milk, yogurt, cream, shallot extract yogurt, pasteurized curd and various cream cheeses...

The ability to fill all kinds of food products such as natural fruit juice and herbal extracts, honey, breakfast chocolate, cultivated olives, aloe salad, malt extract, peanuts, etc.

It has a PLC control system with a lifetime warranty

Equipped with a gelatinous dater

It has a piston filler and the ability to draw liquids from the tank

The speed of 1000 to 2000 glasses per hour depending on the type of glass and product

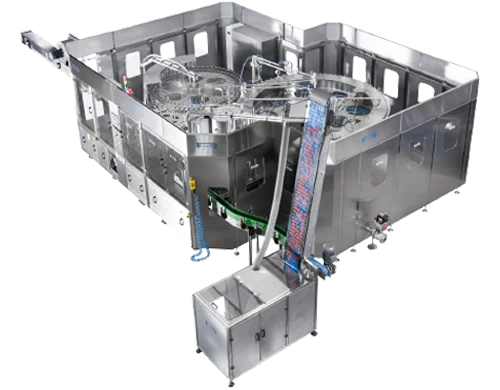

Rotary filling machines move containers down the production lines through different circular stations. At these points, the conveyor passes under rotating star wheels. Containers are centred under the filling head and once full, they move to the next stage.

Rotary liquid filling machines can handle large-scale and high-speed filling production. In this type of machine, the containers are moved around circular stations, where specific functions such as filling, capping (cap placement and cap re-torque), sealing, sleeving, etc.

Rotary machines are powered by a motor that spins in a vertical circle. The needle bar is attached to the motor to move the needle up and down. Rotary machines are less customizable and require substantially less knowledge and finesse to be used effectively.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Packaging Machines

Packaging Machines