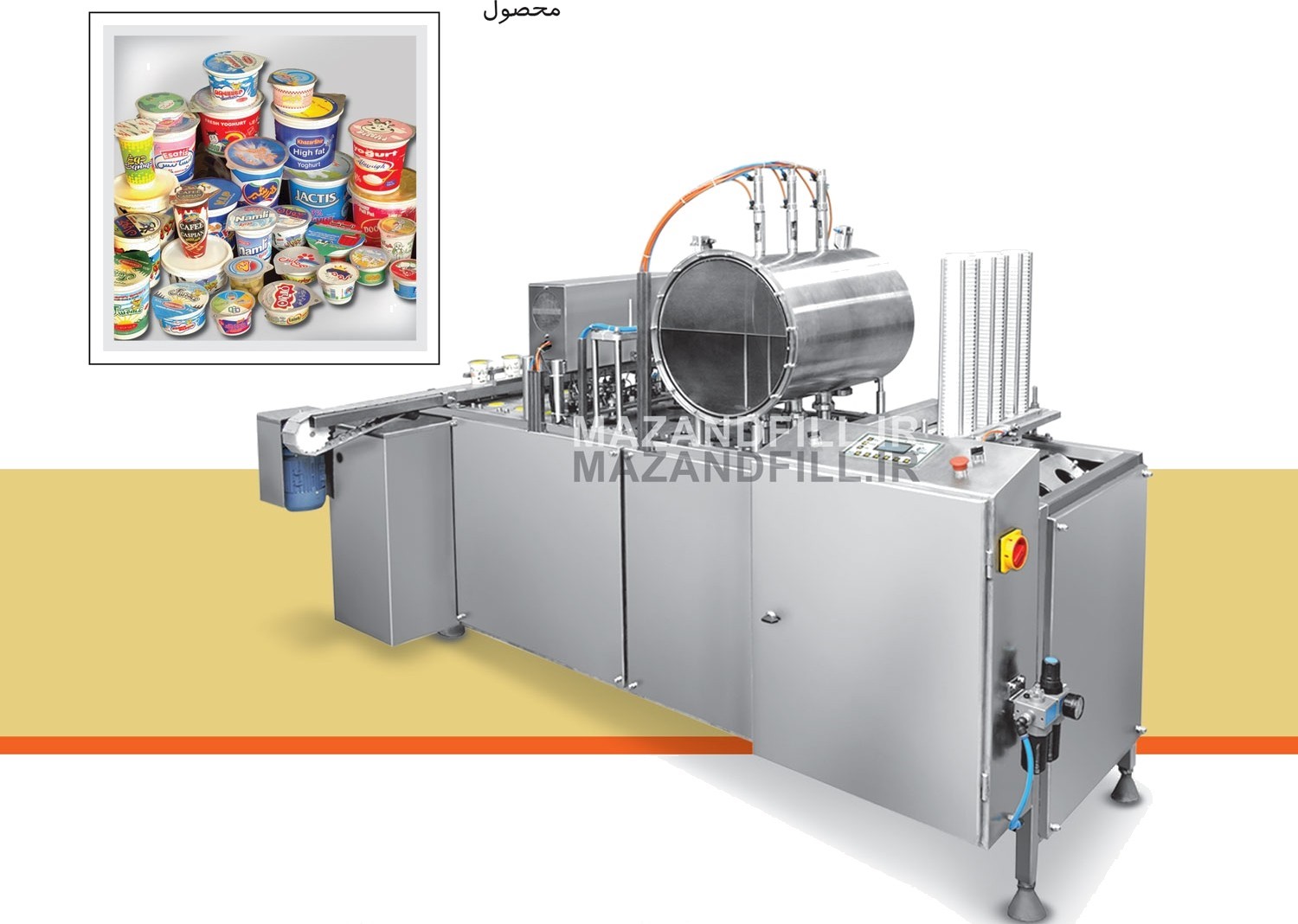

The ability to fill all kinds of dairy products such as school milk, cocoa milk, yogurt, cream, shallot extract yogurt, pasteurized curd, and various cream cheeses, etc.

The ability to fill all kinds of food products such as natural juices and herbal spirits, breakfast chocolate, etc

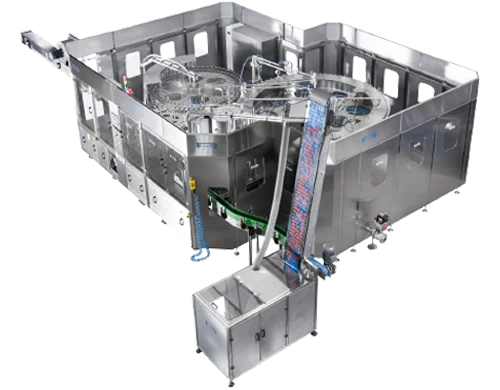

Equipped with PLC control system and touch screen display

The ability to connect to the central CIP system

Equipped with UV rays and foil sensor

Ability to control each line separately

The speed is 4000 to 4500 glasses per hour, depending on the type of glass and product

Linear filling machines have been part of production lines for decades. These machines fill containers passing down a conveyor system using gravity, pistons or pumps. Linear machines fill bottles in sequence. They stop to fill each batch of bottles before moving to the next.

Linear machines, also known as linear classifiers or linear models, are a class of machine learning algorithms that make predictions based on linear combinations of input features. They are commonly used for classification and regression tasks.

Although linear machines are highly accurate, they can be limited in terms of production speed compared to rotary machines, which often offer higher speeds to maximise industrial efficiency. Furthermore, because of their in-line layout, linear machines can require more space in the production line.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Packaging Machines

Packaging Machines