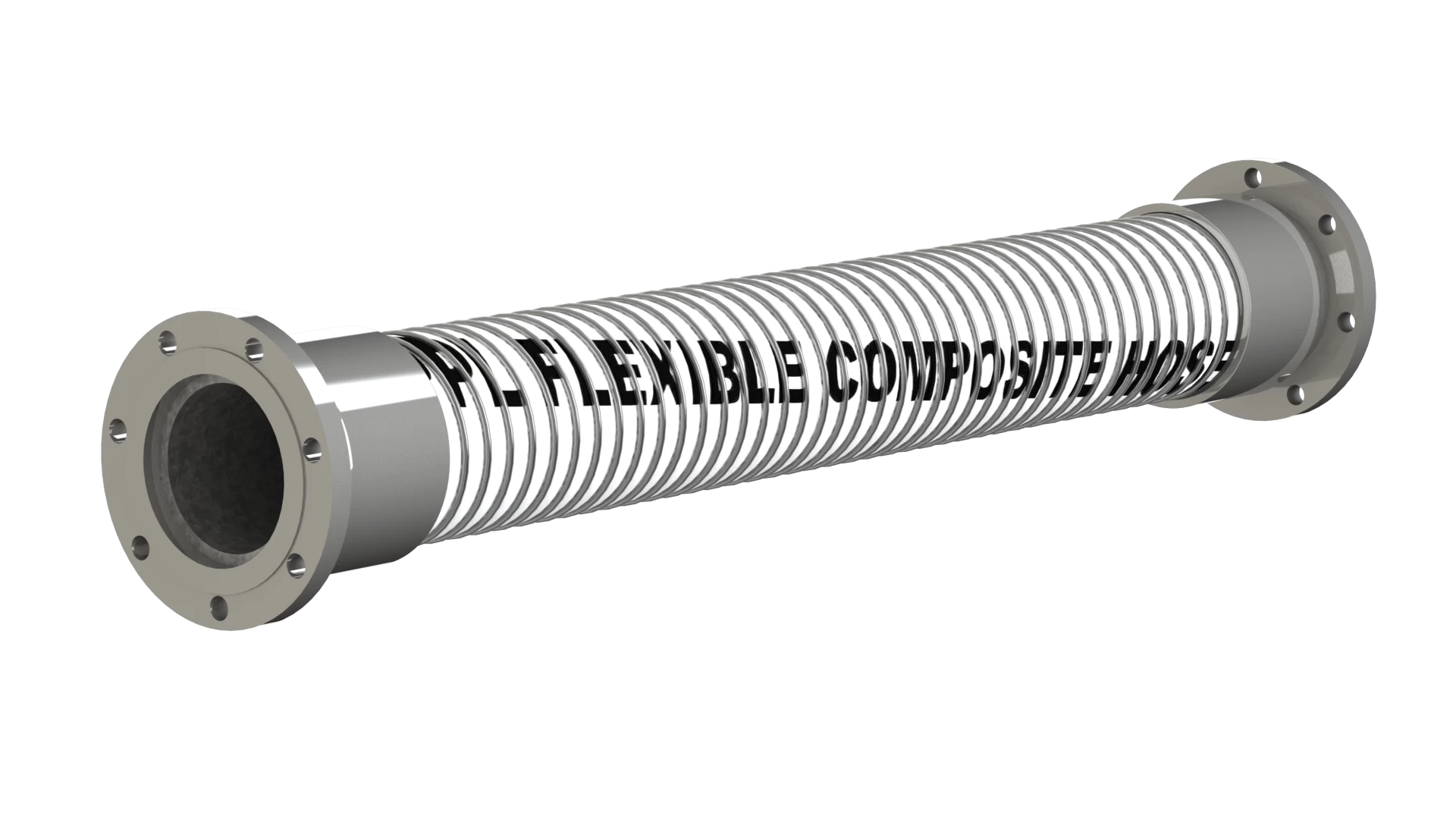

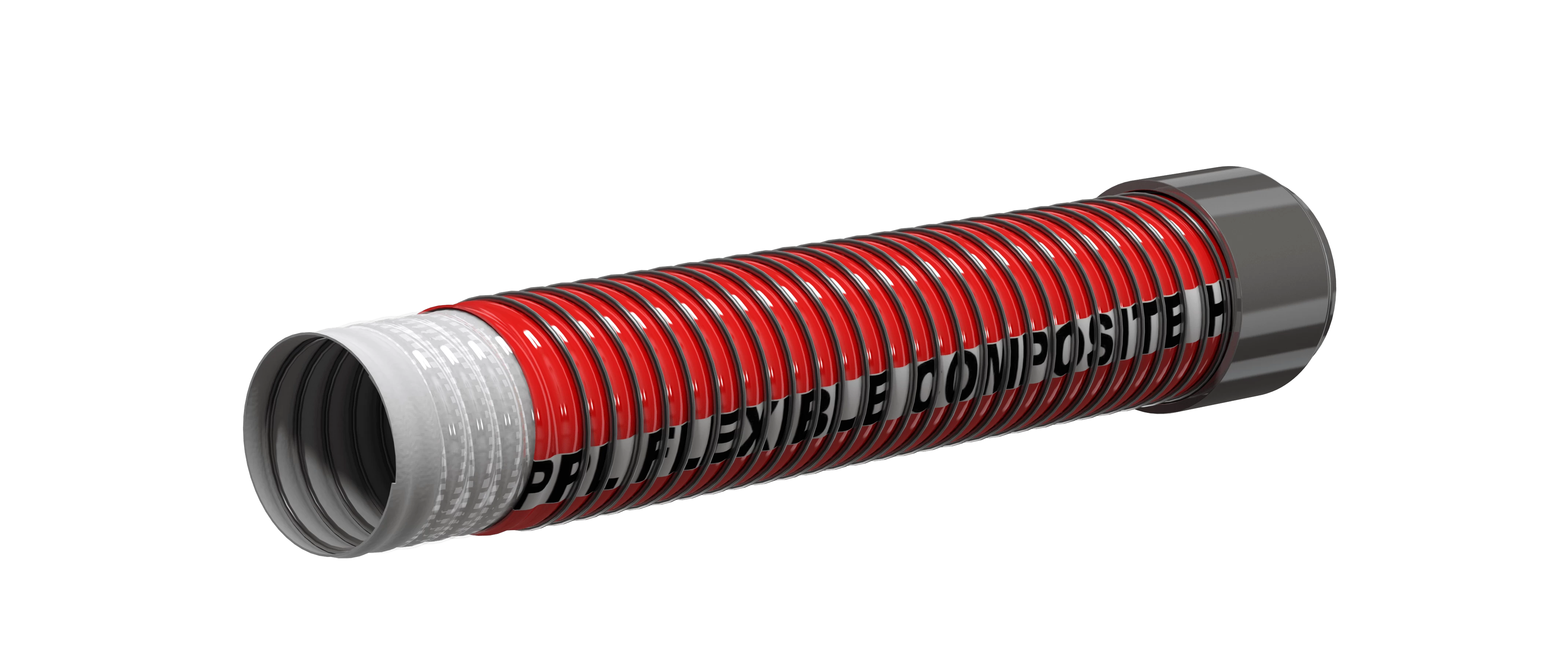

Flanged hose fittings are fittings that have flange fixed on. We can know the product consists of a fitting and a flange. The material of the fitting is often SS 304 or SS 316. And the flange is made of SS 304. There is a serrated profile in the hose tail of the flange coupling. We also have different types of elbow flange heads.

How to fix a flange?

Remove broken flange. Remove the broken or corroded sections of the flange.

Apply silicone. Apply a liberal amount of 100% silicone sealant to the top of the remaining parts of the flange.

Install new Johni-Bolts. ...

Install Repair Ring. ...

Secure Bolts. ...

Allow silicone to cure.

Flanges are used to connect pipes with each other, to valves, to fittings, and to specialty items such as strainers and pressure vessels. A cover plate can be connected to create a "blind flange". Flanges are joined by bolting, and sealing is often completed with the use of gaskets or other methods.

A broken flange will cause the toilet to move because it is no longer secured to the flange, which is anchored to the subfloor. The constant rocking will likely break the wax seal (located between the toilet and the flange), allowing water to leak onto the substrate and the ceiling below when the toilet is flushed.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Other Tools

Other Tools

.webp)