Apart from different filling mechanisms, the liquid filling machine is also designed and implemented in two types of linear filling machine and rotary filling machine . One of the biggest advantages of rotary filler is occupying less space in the factory, which distinguishes it from other linear filling devices.

In linear filling and packaging lines, to perform at least 3 jobs on a container, about 6 meters of space is needed, but in rotary filling of liquids with the same work forecast, the maximum space it needs is 1.5 meters by 1.5 meters. Was. Filling with the help of two nozzles, one for feeding and the other for finishing, and the mechanism for capping the bottle and capping it with the help of an aluminum head are the main mechanisms of this liquid filling machine . Filling capacities between 250 cc and 4 liters are among the features of the device at the time of production

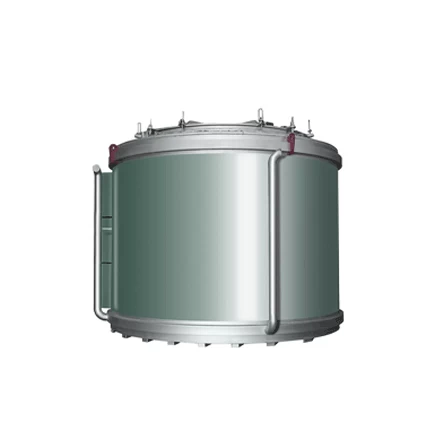

In the factories that produce liquid materials, the form of packaging has many variations, including 220 liter barrels. Pandar Sanat has helped in this field by producing special machines such as 220 liter barrel filling machine . This device includes a liquid filling device that can fill all kinds of liquids such as water, syrup, juices, radiator water, edible oils, industrial oils and such products into the barrel.

Using the load cell system to measure the weight of the materials inside the barrel is one of the most accurate filling systems. In the samples of the semi-automatic barrel filling machine, the bottom part on which the barrel is placed uses round weed rollers to help the barrels move easily on the machine. The nozzles of the barrel filling machine can be increased upon request. These nozzles are mobile and enter the barrel automatically at the beginning of filling and perform the filling process. Also, a mechanical drip catcher is used on the nozzle so that when the work is finished and the nozzle comes out from inside the barrel, it is placed under it and prevents the material from dripping on the barrel or part of the device.

It is very easy to work with the barrel filling machine , and the barrels move easily on the roller with low hand pressure.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Other Machinery & Industrial Equipment

Other Machinery & Industrial Equipment

.webp)