Silicon carbide plate

Silicon carbide plates have a high working temperature.

Among their features at high working temperatures:

oxidation resistance,

corrosion and chemical reactions,

Excellent chemical stability.

rapid increase in temperature in it,

long life,

resistance to bending and warping at high temperatures,

Easy installation and maintenance.

Product details - technical specifications

Silicon carbide plate is produced from silicon carbide powder as the main material and the addition of some additives and antioxidants that effectively increase the softening point and improve its antioxidant properties. Silicon carbide plate has many advantages

. which makes it suitable for use at high temperatures.High

flexural strength at high temperatures

Very good shock resistance

Good thermal conductivity Good

wear resistance

Chemical resistance and good stability in different atmospheres

Silicon carbide with long-term use It does not change shape at high temperatures.

It has good thermal conductivity at high temperatures.

It is a very suitable material in industrial furnaces to reduce energy consumption and as a thermal shield against flames.

With this material, it is possible to significantly:

• raise the furnace temperature

• prevent energy waste

• improve the productivity and economic efficiency of production.

One of the main applications of silicon carbide plates is to make alloy deoxidizer materials for steel production .

Phosphorus (P) and sulfur (S) are impurities that have a great impact on the quality of steel.

When the silicon carbide plate has more phosphorus, ferrosilicon powdering is easy and easy to do.

When the furnace temperature is reached, it can be fed and melted. It is better to treat the 4s Ferrosilicon first, to quickly restore the condition of the furnace, so that their performance returns to the same as when the furnace was opened.

Due to the presence of sulfur (S) and silica (Si) in the melting process, silicon sulfide is formed: such as SiS, SiS2 and other compounds, these compounds are easily vaporized and removed at high temperatures, so there is no need for the presence of sulfur silica. .

Features of silicon carbide plates

- High strength at high temperatures. Compared to other materials, there is no change in shape during long periods of use at high temperatures. By using plates with optimal and less thickness, compared to other refractory plates, the efficiency of furnace work is increased and energy waste is minimized.

2. SiC plates have high compression, a smooth and soft surface, and do not cause any pollution or impurities during use.

3. They have high resistance to rapid cooling and heating and do not crack easily during use.

4. Wide temperature range for cooking; It can be used from 800 to 1400 degrees Celsius.

5. High thermal conductivity, excellent corrosion resistance at high temperatures and excellent wear resistance

6. It has a very good antioxidant performance, compatible with oxidizing environments and atmospheres and reductive firing of ceramics

7. Excellent compressive and bending strength at high temperatures. Can use one side for a long time without turning it over or changing its shape.

In normal cooking conditions, it can be used 500 to 1000 times without the need to turn it over.

applications

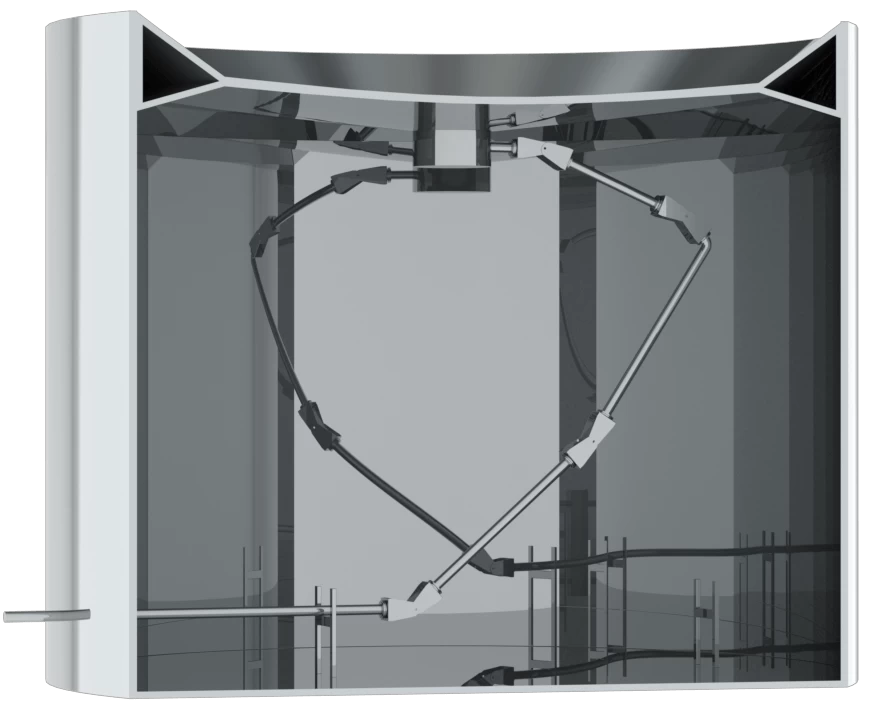

In shuttle or roller tunnel furnaces up to 1450 degrees Celsius

• For baking sanitary porcelain ceramics

• For baking container and household porcelain

• For baking electric porcelain

It is stable at high temperatures and does not change shape with high bending strength.

It has very good plasticity resistance and does not break.

It has a long life.

Its normal service time is over 200 cycles.

Also, due to the high thermal conductivity of silicon carbide in furnaces and its excellent heat transfer efficiency, the use of this material saves energy by more than 30%.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Other Construction & Real Estate

Other Construction & Real Estate