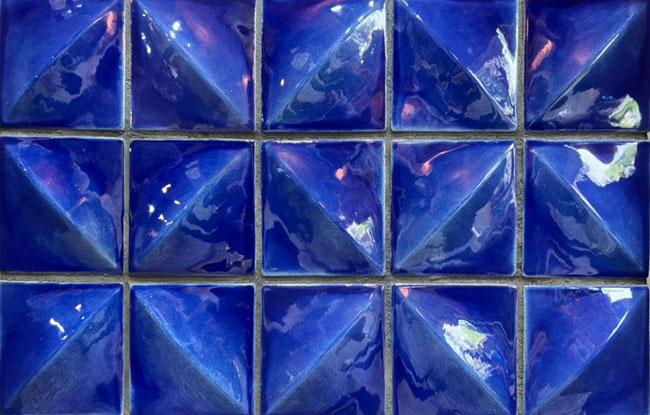

Blue and red glazed concrete nanobrick materials are produced with maximum absorption and very long durability. Blue and red glazed concrete bricks are completely different in terms of texture and color, the colors are vivid and light, dark and patina. It should be noted that the colors applied on concrete bricks are processed in a 360-degree humidity oven.

Blue and red glazed concrete nano-brick materials are produced with maximum absorption and durability. Blue and red glazed concrete bricks are completely different in terms of texture and color, the colors are vivid and light, dark and patina.Decorative blue and red glazed concrete bricks and classic golden soil with polymer compounds and materials consisting of mineral materials and light-grained concrete are produced under the supervision of experienced experts. Blue and red glazed concrete bricks comply with construction standards and are compatible with all kinds of weather conditions. Due to the type of polymer compounds used in it, the golden soil concrete bricks do not suffer from dandruff, unlike many other compounds.

The salient features of the blue and red glazed concrete bricks are as follows:

Perceptible weight reduction compared to bricks and conventional building stones: By using light-grained concrete, a significant reduction in product weight has been created. (The weight of each square meter of the product is 15 to 16 kg.)Optimizing mechanical and chemical resistance: The main ingredient of blue and red glazed concrete bricks is polymer concrete, which has higher mechanical resistance than conventional concrete and is highly resistant to chemicals, corrosives and detergents.

Resistant to sunlight and freezing: The polymer compounds used in blue and red glazed concrete bricks cause less water absorption and higher stability against the phenomenon of freezing compared to conventional concrete. Also, these used compounds are highly resistant to UV rays and CO2 gas.Color quality: The colors used in the blue and red glazed concrete bricks are the best types of acrylic colors, whose characteristics are high resistance, color stability against direct sunlight, and washability. It should be noted that Zarin Khaq products have the potential to be produced in a variety of custom colors, except for the standard color code.

Presence of protective surface layer: By using mineral and polymer compounds on the surface of the product, a protective layer is made that is highly resistant to water penetration and gives a high surface hardness to the product.

Dimensions: The size of each plaque is equal to the dimensions of 1.5*6*20 cm, the number of which is equal to 64 plaques for each square meter, including the width of the strap of 1 cm.Another feature of polymer compounds used in blue and red glazed concrete bricks is compatibility with different weather conditions and does not allow the growth and proliferation of any kind of algae, moss and bacteria in the product.

Blue and red glazed concrete bricks have a 5-year unconditional warranty. The warranty includes dandruff, algae, cracking and bursting of bricks, falling from the facade of the building. that all the costs of the scaffolding, infrastructure, installation and new materials are used.

It should be noted that the colors applied on the blue and red glazed concrete bricks are made in a 360 degree humidity furnace.

Send message to author

Blue and red glazed bricks

2023-10-30 18:27:12

Mobile number:

Email:

Address:

Type of activity:

Phone:

Site:

Comments

Related posters

© 2024 Copyright: mallmir.com

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Other Construction & Real Estate

Other Construction & Real Estate