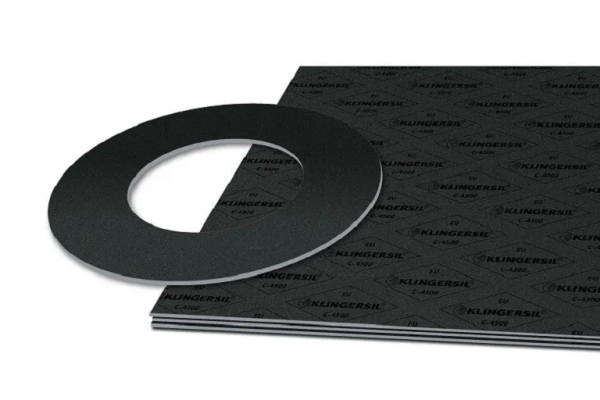

Today, many industries, due to their special features and products, require special types of sheets that can show good resistance to heat, temperature, and fluid in spite of the appropriate weight and thickness. Fiber sheet is one of these things that has been able to satisfy many industrial owners in the last decade and is in more demand in the market day by day.

Although fiber is a product that has been used in the industry for a long time, in the last decade, due to the addition of new compounds and more up-to-date technology, they have been able to improve its characteristics and provide new advantages such as high resistance to heat and weather conditions. add to itIn general, the structure of fiber sheets is made from the combination of rubber, wood, paper, cloth or glass fibers along with resin. These sheets have various applications in industries and the special properties of resin have made it a popular product among engineers and industrial owners. These sheets have a very high thermal tolerance and can act as a very good thermal insulator. Therefore, they are useful in reducing energy consumption for heating or cooling the house. The safety of these sheets is very high, as they are non-conductive and provide excellent strength despite their light weight.The fireproof sheet is very compatible with the space and does not harm the environment. Their light weight can reduce the volume of structures and other products. In some fiber sheets, materials such as aluminum oxide, silicon and magnesium oxide are used, which have anti-flammability properties and cause the fiber sheets to burn. If in your industry the equipment is in close proximity to corrosive substances such as acid or other chemicals, using anti-acid sheet can be a good choice, because these materials are also resistant to corrosion.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

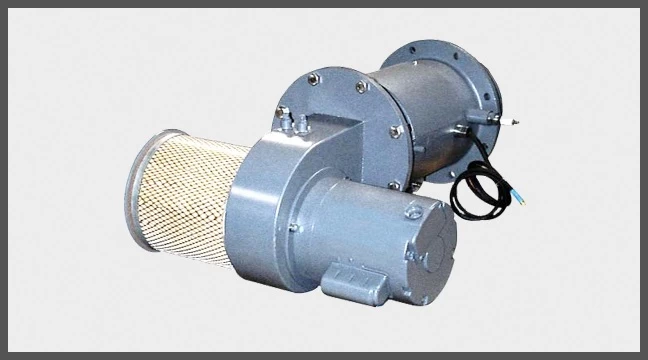

Industrial equipment

Industrial equipment