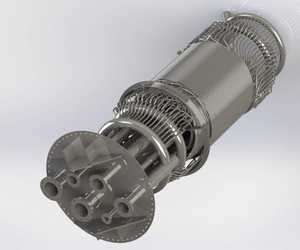

Coil Wound Heat Exchanger or Bath Vaporizer is one of the special heat exchangers made by Hilavis experts for use in cryogenic units.

The design and manufacturing technology of this type of converter is monopolized by a handful of well-known companies due to its complexity.

Coil converters consist of several bundles of tubes that are strung on top of each other and around a cylindrical cylinder, so each bundle of tubes can represent a flow. In the shell of this converter, a cooling or boiling fluid such as water is placed and it is used for the following applications:

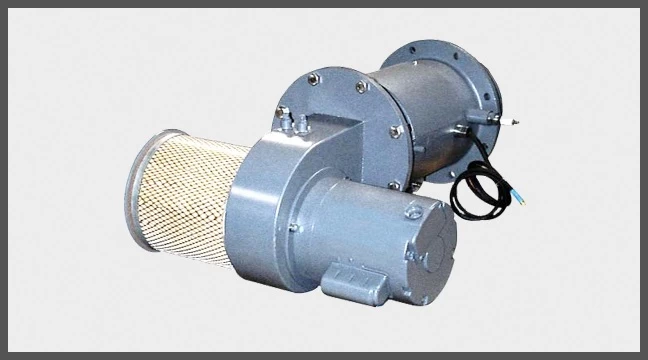

Heater/cooler

Fluid condenser

Fluid vaporizer

Isothermal reactor

This type of converter can be made of austenitic stainless materials, aluminum alloys and nickel alloys.

The advantages of this type of converter compared to other converters include a wide range of operating temperature and pressure, the use of multiple streams in one unit, high surface to volume ratio and high compression, high heat transfer, the ability to be used in high pressure services, and the high capability of the converter. In order to facilitate the conditions of Start up, Shut down and Plant Trip, he pointed out.

The more advanced generation of these converters is the Spiral Wound Heat Exchanger type, where the main fluid (Main Stream) is flowing inside the shell and at the same time it is exchanging heat with all other currents. This advanced type has only been used by two reputable American and German companies in LNG units.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial equipment

Industrial equipment