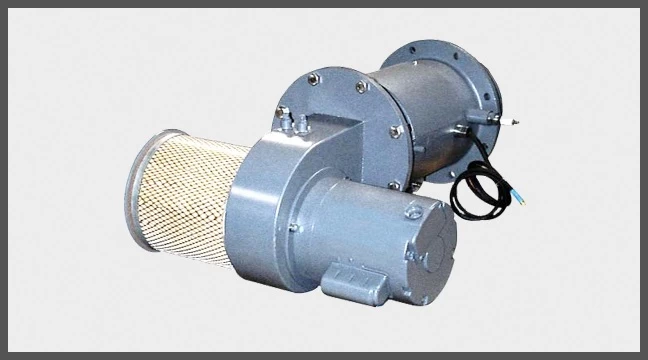

Surface Condenser, as one of the peripheral equipment of steam turbines, is responsible for distilling the low pressure suction output of steam turbines and is designed and manufactured according to the HEI standard.

This equipment preserves the thermal energy in the steam and reduces the energy consumption in the boilers, prevents the wastage of demineralized pure water and optimizes the energy in the units where multi-stage steam turbines are used.

These heat exchangers are different from other exchangers in several ways:

Operating pressure with relative vacuum for Shell

Shellside fluid phase change on the surface of the tubes

Direct shell side connection to the ejector

Cooling with sea water

Rectangular sections

In recent years, with the development of alloys and the evolution of the cost of titanium production, the use of this resistant metal in seawater condensers has been growing. Replacing this material with traditional material such as capernickel requires thermal and mechanical redesign of surface condensers and increasing useful operational life and reducing their losses.

For the first time in the country, Hilavis has successfully designed and manufactured two rectangular titanium surface condensers.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Industrial equipment

Industrial equipment