Types of flooring

One of the most important and main beauties of the interior and exterior of the building is the floor design. In the past, floors were usually made of wood. After the passage of time and the advancement of technology, with the arrival of parquet and flooring with a material and design similar to natural wood, most of the houses used wooden parquet for the flooring of the house. Now there are newer products known as plastic wood or plastic wood. Plastic wood flooring is mostly used for indoor and outdoor floors of buildings.Use of plastic wood as flooring

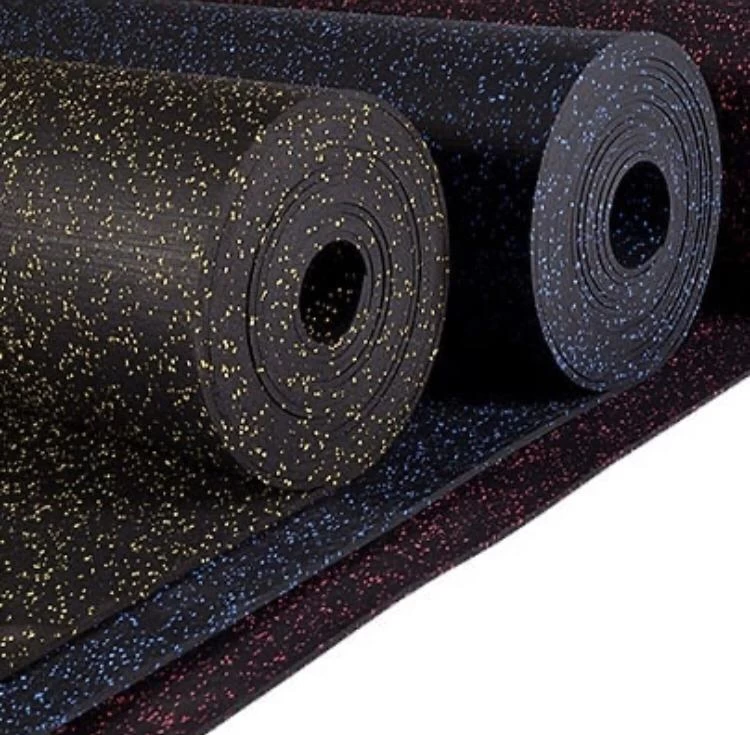

The applications of plastic profiles or wood are to be used as flooring, especially in outdoor spaces and open areas. Due to the high durability compared to the environmental conditions, plastic wood flooring is easily used in open spaces and exposed to various environmental factors, it has high efficiency and durability.

Plastic wood is used as flooring for roof gardens, gazebos and pergola. Plastic wood can also be used to cover the pool and the area around the pool.Some of the important uses of plastic wood flooring include yard flooring, pool decks, terraces, commercial center floors, restaurant floors, lobby floors, dock floor coverings, rooftop flooring, bridges such as nature bridge, park floor design, sauna flooring, and more. .

What features are important for plastic wood flooring?

In case of using plastic wood profiles as flooring for outdoor spaces, check the amount of water absorption, the resistance of plastic wood to the amount of abrasion, the abrasion resistance of plastic wood, the amount of resistance to uv and color stability, resistance to environmental conditions such as thermal expansion, swelling Due to humidity, water absorption, decay, resistance to termites and fungi are required.enviromentalist

One of the characteristics of plastic wood products is compatibility with the environment. Environmental problems regarding waste recycling are increasing daily. Increasing the life span and durability of materials and materials used in the construction industry such as wood is essential, and on the other hand, it should be noted that one of the criteria considered by the users of plastic products is to reduce dependence on chemicals, because the cost of raw materials is constantly increasing. It is an increase.Compared to traditional wooden products, plastic wood products increase the required efficiency to a great extent and are reasonable options to be compatible with nature.

The use of plastic wood has little waste. Even a small amount of waste can be recycled. There are no organic compounds in the structure of these products. Another feature of them is the ability to recycle and reuse after the end of the efficiency period. The resulting waste is not dangerous and can be disposed of using standard methods.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Flooring & Accessories

Flooring & Accessories