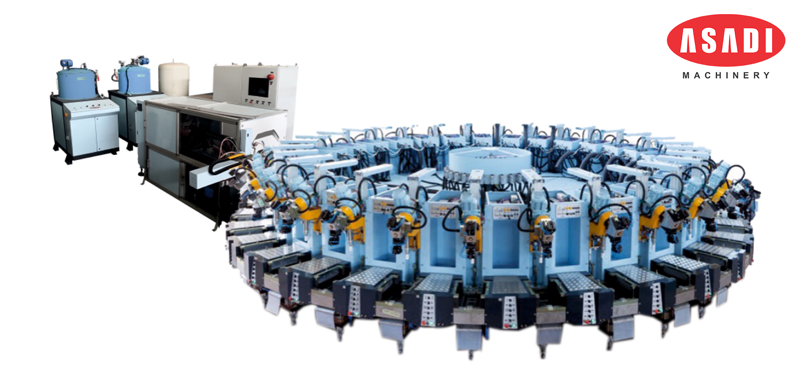

PU direct injection machine with 24/30 stations

The highest quality

The best adhesion of the sole to the upper

Disappearing bubble in sole

Gasoline direct injection (GDI), also known as petrol direct injection (PDI), is a mixture formation system for internal combustion engines that run on gasoline (petrol), where fuel is injected into the combustion chamber.

Direct Fuel Injection is nothing more than an injector delivering fuel directly into the cylinder of an internal combustion engine. It is a relatively new concept - first seen in the mid 90's in diesel engines but has more recently had a widespread adoption in gasoline engines.

PU injection, also polyurethane grouting or injection, is a water- proofing technique that uses expanding injected polyurethane to prevent water flowing through and voids or cracks typically in concrete.

Direct injection is the process of introducing a molten material, commonly TPR, PVC or PU, into the cavity of a mold to achieve the desired shape. This process can be used for the production of outsoles, decorative details or to join an outsole to upper directly. The latter is known as DIP or Direct Injection Process.

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Apparel & Textile Machinery

Apparel & Textile Machinery

.webp)