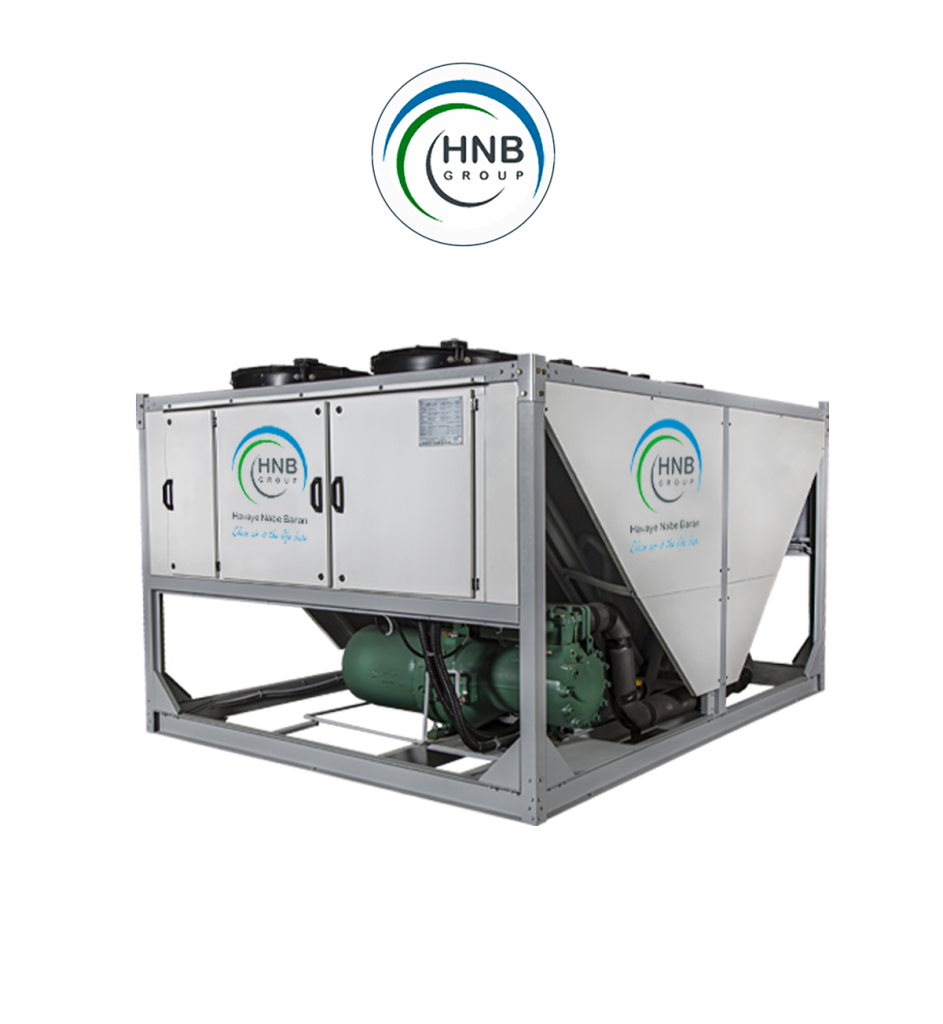

Production in capacity range of 5 – 400 TR in one unit

Enable to modulate chillers to each other up to 5 units

Most known European brands of compressor (Bitzer, Danfoss, Copeland, etc.) with high efficiency and special to tropical weather condition

Each compressor works in a separate circuit in all units.

Enable to use Economizer system in screw type compressor according to customer’s inquiry

Enable to consider three refrigerants of R134a, R407C and R22 in the units

Structure made of galvanized sheet with 2 mm thickness. All the cutting, punching and blending of metal components are done by TRUMPF branded advanced CNC machinery according to confirmed drawings.

Body is made of 1.25 mm thickness of galvanized steel which is electrostatic powder painted with 80 μm thickness.

Chassis and profile painting by Polyurethane liquid with 120 μm thickness

Up to 50 TR nominal capacity, chassis made of galvanized sheet connected by bolts and nuts. In higher capacities in order to have more strength, chassis is made of standard girder and channel beam.

Installing the Receiver with pump-down capability

Electrical components of high quality brands as Siemens, Danfoss, Schneider, LS, Hyundai, Finder, Autonics and Technology

Valves of refrigeration line of Western European high quality brands as Castel, GMC and ALCO

Equipped to controllers of high/low pressure, oil pressure and oil level to protect the compressor

Fans of axial type with maximum airflow and minimum noise

Equipped to PLC based controller as CAREL, DANFOSS, etc.

Send message to author

Condensing Unit Equipped to PLC

2023-09-17 18:34:20

Email:

Address:

Type of activity:

Phone:

Site:

Comments

Related posters

© 2024 Copyright: mallmir.com

+7929688-88-14

+7929688-88-14

English

English

Persian

Persian

Russian

Russian

Chinese

Chinese

+7929688-88-14

+7929688-88-14

Air condition machinery

Air condition machinery